+44 75754 30035 help@rapidassignmenthelp.co.uk

offer

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

Hydraulic jacks are very useful in many sectors such as the automotive industry, construction fraternity and production line because of its capacity to lift large weights with ease. These devices work on Pascal’s law that tackles pressure acting on a fluid in a confined space is always felt at the same level throughout the fluid (More et al., 2021). This principle makes hydraulic jacks to produce much larger force and they are highly used when it comes to lifting chores that require high force.

The hydraulic jacks, based on their design and operation, have sunk through measured changes for many years. Over the years, new materials and technologies have been incorporated into hydraulic jacks whereby they have improved their efficiency significantly. For instance, integration of motorised systems in hydraulic jacks has enhanced it by making it easier to operate and having better performance as noted by More et al. (2021) Design and fabrication of motorized hydraulic jack system. In their work they underline the understanding the need for improving the mechanical part as well as the control systems to enhance its efficacy.

Besides, hydraulic jacks have been invented to perform more than the basic lifting function. Wahrhaftig et al. (2024) investigated how hydraulic bottle jacks could be useful in the management of vibration and effects of the earthquakes. They note that the application of hydraulic jacks is very wide in achieving different engineering solutions like supporting structures during an earthquake.

In pursuing this development, this project is attached on the belief and proposition that the existing concepts and technologies can be enhanced to create a comprehensive concept of hydraulic jacks in small, medium, and large scales. Using MATLAB for computation design, the project aims at proposing a general solution that fulfils the reasons that different manufacturers may present. Though, the conceptual design will pay much attention to the variation of the major characteristics of the piston-cylinder mechanism and the length of the lever to improve stability and safety. Also, the sustainability impacts and ethical viewpoints will be provided, where the effective contrasts will be made in order to meet engineering standards and conditions of present days.

Reference materials and sample papers are provided to clarify assignment structure and key learning outcomes. Through our assignments writing help, guidance is reflected while maintaining originality and academic integrity. The Design And Analysis Of A Hydraulic Jack Using MATLAB Assignment Sample demonstrates technical design processes, MATLAB simulations, and analysis of mechanical systems. These resources are intended solely for study and reference purposes.

Get assistance from our PROFESSIONAL ASSIGNMENT WRITERS to receive 100% assured AI-free and high-quality documents on time, ensuring an A+ grade in all subjects.

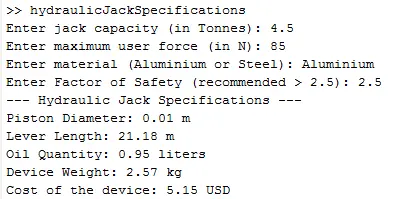

Figure 1: Design Inputs Hydraulic jack

The use of a hydraulic jack requires several parameters that define the capability of the hydraulic jack at work. The essential prerequisite information for this project involves the jack capacity, maximum force that the user will apply, the material to be used, and the factor of safety. The load of the jack is also measured in tons and it estimates the capacity of the jack to bear a certain load. Concerning to the capacity this is something that was set at 2 tons, this is a standard degree of capacity that is often found in most industries.Design And Analysis Of A Hydraulic Jack Using MATLAB Instead the maximum user force is limited at 85N to make the jack user friendly in that it can be easily operated.

Material selection in this case is important because it is associated with both weight and cost of the device. It was mentioned that the user can select between aluminium and steel which has different characteristics. Aluminium is lighter, weighing 2700 kg/m³ and costs $2 per kg, and is thus cheaper while steel is denser: 7800 kg/m³, and costs $5 per kg, and is stronger as well as more durable. On these designs the best material to be used was aluminium so a s to reduce the system’s weight.

The factor of safety (FoS) is an important control variable that will assure that the jack can support even loads that are beyond the rated capacity of the part. A FoS of 2.5 was chosen in accordance to industry practice to ensure both safety and the utilization of materials.

Several factors were taken into consideration when developing the model in order to make it practical and secure as presented below. In the hydraulic system, hydraulic pressure was adjusted at 100 MPa to match with the typical working pressure of most hydraulic systems. The design also has to be restricted to size that will allow it to be used in as many settings as possible. Moreover, it also considered economic demand in that the cost and weight of the device were minimised to make it lighter and more affordable to consumers.

The method applied in this work involved calculation by using systematic formula in determining the specifications of the hydraulic jack. Starting the design process with the user-defined parameters in MATLAB, the next steps were taken. Subsequent to the calculations involving the jack capacity and hydraulic pressure, the piston area was determined in order to find the piston diameter. These values were calculated in order to meet the required force that the user needs to apply on the lever and taking into account the factor of safety (Amlashi et al., 2021).

The amount of oil used was determined by the volume of displacement of the piston and gave a likelihood of the hydraulic fluid needed for the equipment. The weight of the device was estimated with the help of volume of the main parts and given density of the material. Finally, through the process of multiplication the price was arrived at by multiplying the weight of the chosen material by the cost per kilogram of the material.

Ethics regenerated architectural design also prevailed in the conceptual approach to this project because of the following reasons: This situation is achieved when the design provided a choice between the use of aluminium and steel as the main material. In view of the traditional materials being heavier and relatively costly, aluminium embraces sustainable production as it is lighter meaning that few resources will be used when getting materials from the source.

Furthermore, the incorporation of the factor of safety guarantees the security of its users and assures that the device does not fall under risky extremes for lasting durability. MATLAB’s use also has the added advantage of adopting good design principles to reduce conflicts and finalize satisfying designs for various products and systems.

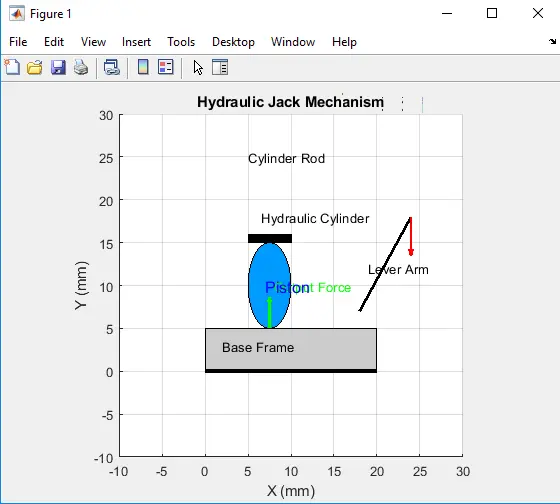

Figure 2: Mechanical design of Hydraulic jack

The hydraulic jack mainly contains two components that are the piston and a cylinder and a lever arm which play important roles in giving the mechanical advantage as well as the support of the load. Starting with the piston area one must define what the jack capacity and hydraulic pressure will be for the design that is being evaluated. The piston area formula describes the formula for calculating the area of the piston as follows:

As the maximum load has been converted to 20000N and hydraulic pressure is 100 MPa, then the area of the piston, Design And Analysis Of A Hydraulic Jack Using MATLAB From the piston area, the piston diameter is calculated using the area of circle formula as shown below:

This gives a piston diameter of approximately 0.01 meters which is similar to the MATLAB calculated value.

It is then designed to provide an appropriate lever arm length to meet the maximum requirement of user force. And the length of the lever is given by:

The maximum force a user is allowed to apply to the lever is 85N and, therefore, the factor of safety is 2.5:

This length allows the user to operate the jack at the required force and the factor of safety affords a safety margin in case of occurrence of unexpected loads.

The mechanical design also involves the determination of the amount of oil needed for the operation of this design, which is based on the volume of the piston displaced. The amount of oil that would be included in the total fuel consumption plan is computed as:

They retain a fuel requirement of about 0.19 liters of oil.

MATLAB Program used in this project is aimed at calculating the hydraulic jack parameter from inputs provided by the user. The code asks the user or a specific person to input the value of jack capacity, maximum user force, and the type of material and factor of safety. From it, the necessary computations for calculating the piston diameter, lever length, amount of oil, the weight of the device as well as the cost are conducted.

It follows a simple structure divided into sections, and this means simple to alter and expand the code. It starts by declaring several constants like hydraulic pressure and default safety factor. The input is taken by extra function input and depending on the selection of the user, material properties are decided. The code following calculates the piston area, piston diameter, length of lever arm, quantity of oil, weight of the device, and the cost, and then shows the values with ease.

With reference to the design process, it can be noted that the MATLAB tool helped increase the speed and precision of the calculations. Design And Analysis Of A Hydraulic Jack Using MATLAB, It was possible to experiment with various options for layouts and perform numerous calculations much faster due to the automation of routine tasks. This brings a level of versatility when it comes to incorporating the various materials and safety aspects into the code, to be adopted in the future designs.

The calculated lever length of approximately 9.41 meters is rather lengthy, which is not suitable for the practical usage in many scenarios, which means that further optimization or application of some restrictions should be made. The mechanical design of the hydraulic jack and MATLAB code belongs to high reliability and can be used for further development. Combining what is done computationally with the knowledge of mechanical engineering, it leaves little doubt whether the design is not only theoretically valid but also physically possible. The focus on the design process review explains the weaker design areas and prepares the ground for future developments on hydraulic jack development.

The modelling and simulation of the hydraulic jack helped in understanding both the mechanical and computational part of an engineering design. The MATLAB code is also useful in quantifying various specifications such as the piston diameter, length of the lever, and amount of oil to be used in the vehicle fabrication process to show the possibility of automating the fabrication process. There are some practical concerns mentioned, including the very impractical lever length of approximately 9.41 meters. This presents an indication that there is need to enhance equations and design using other methods that are more practical in real life.

The use of materials including aluminium and steel still give the advantage of variety of weights that is friendly to the environment and cost aspects of sustainability. There are also the question of material strength in relation to cost when designing the product. Thus, the factor of safety remains certain, but the following ones could be improved by applying dynamic factors considering certain application demands.

Conclusion

Thus this project has achieved a successful combination of theoretical knowledge and practical engineering implementation in designing the hydraulic jack. MATLAB applied in computational design improves the certainty of the designs and lays solid ground to advancement. Though this arrangement has problems, especially as far as the length of the lever is concerned, it is possible to continue further development from this design. Further studies should be conducted based on the refinement of the lever mechanism or the search for new materials, and from the user’s perspective. Further, the use of better optimization algorithms in the MATLAB code could enhance design results as well. By addressing these areas the project will be in a position to improve on the hydraulic jack and probably matched it with the market standards and the client requirements.

References

Introduction: Legal Issues: Health And Safety In The Hotel Industry...View and Download

Introduction: Leadership and Change management Get free samples written by our Top-Notch subject experts for taking online...View and Download

Introduction to Logistics And Supply Chain Management Assignment Supply chain managing is refers to the procedure of handling...View and Download

Introduction to Academic Study Skills Assignment From steam power to fuel-driven engines, the automobile industry has undergone...View and Download

Introduction Get free samples written by our Top-Notch subject experts for taking Assignment Helper services. It is identified...View and Download

Introduction Get free samples written by our Top-Notch subject experts for taking online Assignment...View and Download