+44 75754 30035 help@rapidassignmenthelp.co.uk

offer

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

The case of Unilever is a strong example of good supply chain management. Unilever's supply chains operate in over 190 countries and manage more than 400 brands, making it a company with very high coordination and responsiveness (Unilever, 2025). In the UK, Unilever’s supply chain sources from global suppliers, produces in a local manufacturing plant, and distributes to its various retail outlets and e-commerce channels.

Logistics management involves planning, implementation, and control of efficient flow and storage of resources from the ‘point of origin’ to the ‘point of consumption’ to meet customers’ requests (Eroglu and Croxton, 2018).

Logistics management is a part of the bigger picture of the supply chain that involves various interrelated processes, including transportation, warehousing, control of inventory, order processing, packaging, and customer service (Khedr and Sheeja, 2024). Therefore, it is the condition that the right products are delivered to the correct location, at the right time, and in the proper condition at the least possible cost. Logistics not only helps a company operating goods to make its flow of goods smooth, but it also helps the company to be competitive by improving service levels, acceleration lead time, and resource optimisation (Mustafa et al., 2024).

Unilever, one of the world’s largest fast-moving consumer goods companies, is a strong example of how logistics management works with other operations. Unilever has several advanced logistics hubs in the UK, utilising automation and data analytics to optimise warehouse operations and transportation routes (Mustafa et al., 2024).

Logistics management is the strategic coordination of the flow of goods in the supply chain from the supplier to the customer (or from the distributors to the store) (Slam et al., 2023). From a strategic perspective, goods are anticipated to be prepared before they are delivered Program Of Post Module. It provides products from one place to another and makes a simple and cheap way to ensure that business goals are met and customer expectations are satisfied (Umair et al., 2019). In the case of logistics management in Unilever, it is crucial to ensure that thousands of products reach the thousands of retail outlets simultaneously and sustainably.

Reference materials and sample papers are provided to explain assignment structure and key learning outcomes. Through our help in assignment writing, guidance is reflected while ensuring all work remains original. The Program Of Post Module Assignment Sample highlights clear task alignment, structured responses, and appropriate academic presentation. These resources are intended solely for study and reference purposes.

Supply chain management deals with the cohesive process that takes place in the making and delivering of a product or service through the life span of the process,, starting from the availability of raw materials to delivering the product to the end consumer (Umair et al., 2019).

Supply chain management is the management of activities across the network from the various points of origination in the supply network (Du, 2007). It includes procurement of raw materials, its production, logistics, inventory management, warehousing, distribution, and post-sales services. To achieve this, there is a need for tight collaborations among stakeholders such as suppliers, manufacturers, logistics providers, retailers and customers to ensure a smooth flow of goods, services, information and finance (LeMay et al., 2018).

Get assistance from our PROFESSIONAL ASSIGNMENT WRITERS to receive 100% assured AI-free and high-quality documents on time, ensuring an A+ grade in all subjects.

A well-managed supply chain can save the day, make your organisation more efficient, and help your firm save costs; at the same time, it can help increase customer satisfaction and improve your company's competitive position (Fabbe‐Costes and Jahre, 2007). Modern supply chains also incorporate digital tools, automation, and data analytics to enhance visibility and decisions across globally scattered networks.

Supply chain management is the complete approach of linking people, products and systems to deliver value, focusing on efficiency and sustainability. Production planning, logistics, and customer service are all part of the movement of goods, but they go beyond that to reach raw material sourcing, supplier partnerships, etc. Supply chain management is essential because it can directly impact business performance and customer satisfaction (LeMay et al., 2018). Managing the supply chain in a complex organisation like Unilever requires keeping costs low and balancing speed, flexibility, and sustainability.

The logistics chain development of Unilever focuses on creating an integrated, efficient, and responsive flow of materials and finished goods across its global and UK operations. It connects sourcing, manufacturing, warehousing, and distribution through coordinated planning and technology-enabled systems.

A Fast Moving Consumer Goods (FMCG) company, Unilever has a strong global presence a vast portfolio of FMCG brands in key areas as food, beverages, home care and personal care. Unilever is a global company founded in 1929 with more than 190 countries of business and brands like Dove, Lipton, Knorr, Persil and Magnum (Unilever, 2025).Unilever’s operations headquarters are in London, United Kingdom, and the company has several manufacturing plants, warehouses, and distribution centres Program Of Post Module. A good logistics and supply chain strategy is the foundation for the company's success. Unilever’s business is organised solely based on sourcing, manufacturing, packaging, warehousing and distribution. These are processes rather than places to get the product to retail outlets and ultimately to the consumer efficiently and sustainably (Vegter et al., 2020). Besides that, the company also focuses on digital transformation and sustainability across the board, which includes logistics using tools such as data analytics, automated processes and low-emission transportation systems to meet both customers' expectations and the environmental goals.

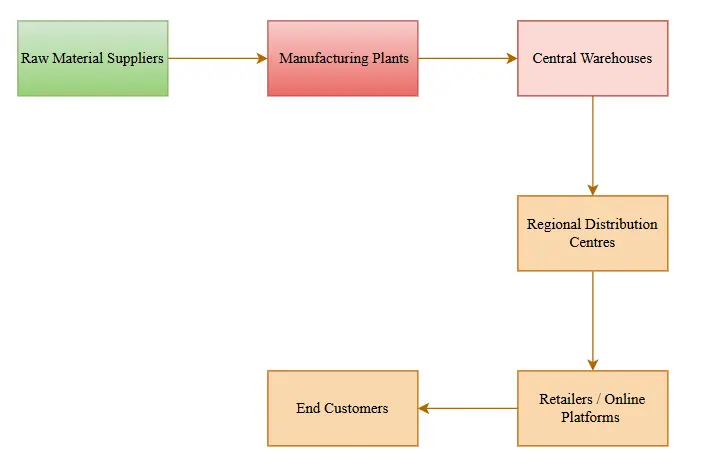

Figure 1: Logistics Chain Diagram

Raw Material Suppliers: Unilever sources raw materials such as palm oil, tea, dairy, and chemical ingredients from a global network of suppliers. This material is first transported to Unilever’s production sites. In addition, the company guarantees that suppliers comply with sustainability and ethical sourcing standards (Ganeshan, Boone and Stenger, 2001). Quality and production continuity depend on the suppliers' selection and monitoring.

Manufacturing Plants: Unilever has several manufacturing facilities in the UK, including the Port Sunlight site, and produces personal care products there. They automate and control the conversion of raw materials into finished goods (Barney, 1991). The efficiency of logistics within the plant, for example, just-in-time delivery and lean production practices, reduces waste and optimises output.

Central Warehouses: Goods are then produced and transported to central warehouses, where inventory is kept and can be consolidated for subsequent regional distribution. These warehouses are also equipped with warehouse management systems (WMS) that can track orders in real time, accurately pick them, and make the most of the space (Gunasekaran and Ngai, 2004). In addition, warehouses act as checkpoints of quality control before products can be released into the market.

Regional Distribution Centres (RDCs): Unilever’s RDCs are strategically located to meet the whole of the UK. The breakdown of bulk shipments for delivery to retailers or wholesalers is dependent on these centres playing a significant role. Transport Management Systems (TMS) plan and coordinate deliveries, which reduces delivery time and fuel consumption (Ganeshan et al., 2001). Mixed load shipping and cross-docking strategies are used to improve vehicle utilisation and delivery speed.

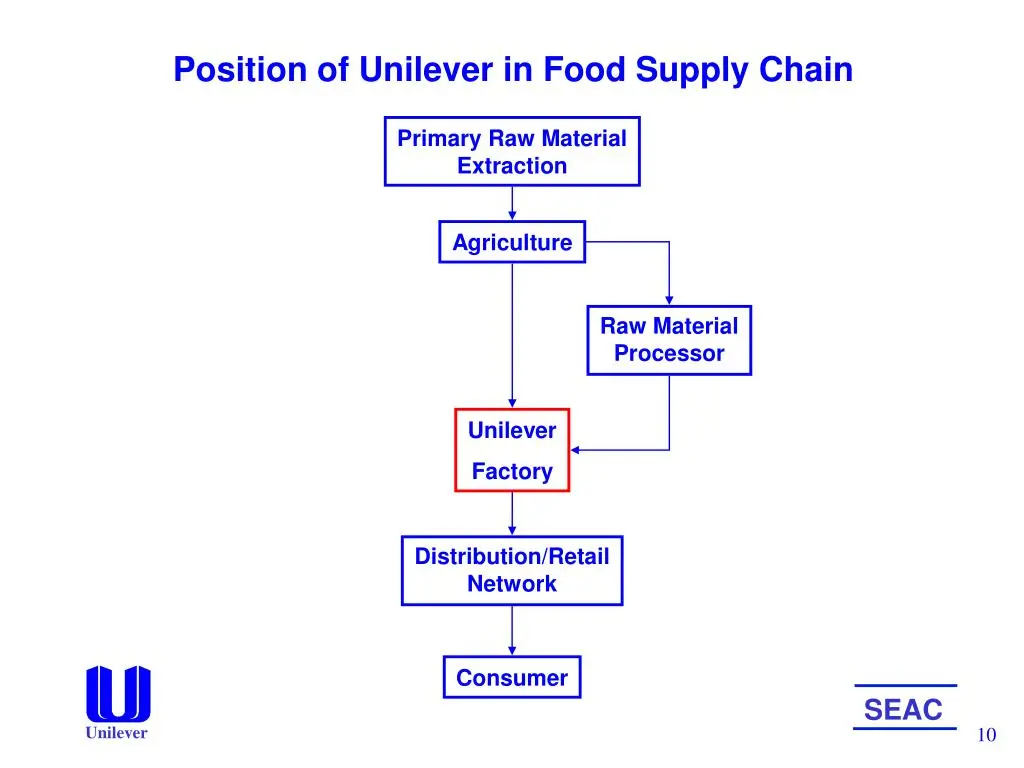

The supply chain structure for Unilever illustrates how materials, information, and products flow from suppliers to end consumers through interconnected upstream and downstream activities. It highlights the relationships between suppliers, manufacturers, logistics providers, distributors, retailers, and customers.

Figure 2: Supply chain diagram

The simple supply chain model explains where the good flows, starting from the raw material supply provider, the manufacturer, and to the end customer (Fabbe-Costes and Jaher., 2007). Sourcing ingredients such as tea or oils for example, from a farmer or a supplier and processing them in a factory (say Port Sunlight for personal care products), and delivering the finished product to consumers via supermarkets or an online platform for example, would be part of Unilever's supply chain (Johnson and Mena, 2008).

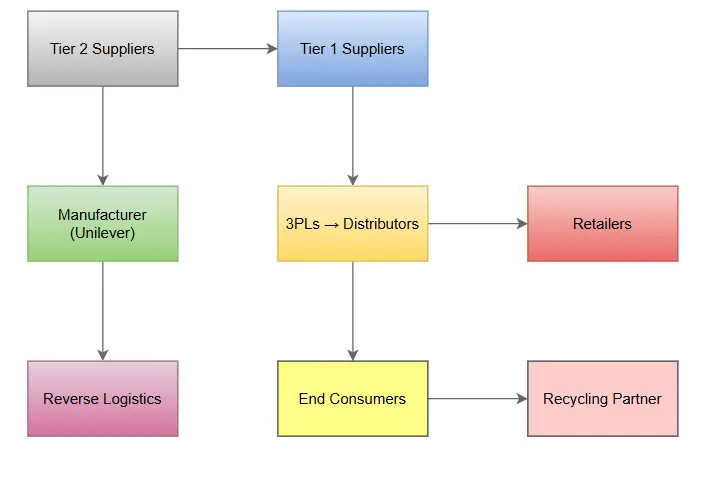

Figure 3: Extended supply chain diagram

Unilever’s upstream supply chain is defined as all the activities and entities from which the company acquires products and services before the manufacturing process. It encompasses sourcing and delivery of raw materials, packaging, components, and process ingredients from a global range of suppliers. Upstream operations of Unilever will involve agricultural producers, processors, and material suppliers providing inputs such as palm oil, tea leaves, dairy extracts, and sustainable packaging material (Lee, Kwon and Severance, 2007). However, some of these suppliers may be in developing regions, which means managing logistics across a range of international borders and requiring ethics and environmental compliance for Unilever.

The downstream supply chain of Unilever includes all the activities after the products have been manufactured, packaged, stored, distributed, sold, and delivered to the end customer. It starts with the transmission of the finished goods from the manufacturing plants to regional distribution centres (Mentzer et al., 2001). The location of these centres is such that they are strategically located across the UK to reduce delivery time and be more responsive to retail demand. Unilever's logistics network moves products to wholesalers and retailers and directs customers through in-house and third-party logistics providers. Downstream includes point-of-sale interaction, e-commerce fulfilment, and customer engagement services (Narasimhan and Kim, 2002). In the last few years, Unilever has increased its downstream capacities through digital platforms where customers can directly buy the product.

The total supply chain includes all the chain processes available in Unilever’s supply network (upstream and downstream). From the procurement of raw materials to the retail delivery of products towards the end consumer, the supply chain covers the whole range from procurement to manufacturing, warehousing, transportation and retail delivery (Narasimhan and Kim, 2002). A level 2 and 1 supplier supplies an essential raw and semi-finished product and transports it to the Unilever manufacturing plant. When the products are produced, they start the downstream phase, usually through the distribution to retailers and customers (can be done through shopping stores or digital platforms). Reverse logistics, the return of unsold goods, recycling of packaging and disposal of waste according to sustainability are also included in the total supply chain (Quesada et al., 2008). Digital systems, which enable real-time visibility, data-driven forecasting and performance tracking of Unilever’s supply chain, support Unilever’s supply chain.

The presence of a supply chain like that of Unilever has a vital role in how a company can perform and acquire a competitive advantage. The supply chain of Unilever is crucial as a multinational organisation doing business in several continents with an extensive product portfolio Program Of Post Module, which depends on the requirements of customers and stakeholders made available. The supply chain is not a support but a fundamental strategic asset whose performance directly affects cost structures, service quality, innovation, and sustainability (Comellia et al., 2008).

This makes it one of the key reasons why the supply chain is important to Unilever as it makes it possible for the company to have consistent product availability across global markets. Brands in these types of very competitive sectors like personal care, food and household products, rely on quick and reliable access from their customers to preferred brands (Barney., 1991). An optimised supply chain enables Unilever to optimise the product flows and streamline product flow, minimising stockouts, reducing delivery times, and ensuring of a high service level. In the UK, consumer behaviour is dynamic, and the behaviour is influenced by seasonal trends, promotions and online retail channels.

Cost efficiency is also contributed mainly by the supply chain. Unilever achieves this through reduced operational expenses without compromising quality through initiatives like consolidated sourcing, lean inventory management and rout optimisation. These savings can be redeployed to improve the company’s long-term resilience through innovation, marketing or sustainability programs (Du, 2007). In fact, Unilever also works closely with logistics providers as well as digitally enabled supply chain planning tools to improve forecast accuracy and adapt fast with demand fluctuations.

The supply chain’s most significant importance is in areas related to sustainability. It is part of Unilever’s view to reduce its environmental footprint through its supply chain operations (Exon-Taylor, 1996). It includes source materials from certified sustainable suppliers, decreases emissions through eco-efficient transport, and reduces packaging waste. Through this, the company can implement its environmental and social responsibility goals. For companies, having a strict supply chain management not only helps to achieve regulatory compliance but also develops the trust of consumers and builds brand loyalty in a moral determined by morals.

The supply chain also provides a conduit for innovation. Unilever’s investment in technology-enabled supply chain solutions has allowed it to adopt automation, real-time tracking and advanced analytics. This innovation increases transparency, enables better decision-making, and makes implementations that accommodate more agile responses to disruptions (Rai, Patnayakuni and Seth, 2006). Unilever's well-developed supply chain infrastructure enabled it to reroute shipments, reallocate resources, and deliver continuity of service to customers during global supply challenges.

References

Introduction Get Free Online Assignment Samples from UK's Best Assignment Help Experts to boost your academic...View and Download

Introduction The business context includes the understanding of elements both internal and external that influence the corporate...View and Download

Introduction Get free samples written by our Top-Notch subject experts for taking online Assignment...View and Download

Introduction Get free samples written by our Top-Notch subject experts for taking online Assignment...View and Download

Introduction to Business Statistics And Forecasting Assignment The link among a group of independent variables as well as a...View and Download

1. Introduction Get free samples written by our Top-Notch subject experts for taking online Assignment...View and Download