+44 75754 30035 help@rapidassignmenthelp.co.uk

offer

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

Flycloud is a Middle Eastern airline that has been experiencing major supply chain and procurement issues that affect its financial as well as operational integrity. In the subsequent years, Flycloud has diversified its business and fleet with the recent addition of the opportunity in the cargo business. Several problems have arisen such as poor procurement policy implementation, poor supplier management, slow spare parts acquisition, ineffective outsourcing, in addition to lastly financial issues. They have led to more cost increases, business interruptions, as well as challenging relations with the suppliers.These issues pose significant threats to the survival of the airline if corrective measures that can arrest the situation are not taken as soon as possible Assignment help In Uk. This report focuses on examining the supply chain issues at Flycloud in addition to providing recommendations for enhancing supply chain procurement, supplier relationship management, logistics, as well as finances. The important domains deal with supply chain system vulnerability, ethical and cultural issues in procurement, outsourcing techniques, supplier management, logistics management, and the application of IT solutions like AI and CPFR systems. In this regard, the financial reviews will include studying the costs and potential savings, as well as expenditures that may be concealed within the procurement and logistics.

In response to these challenges, the research will adopt theoretical supply chain and procurement frameworks, benchmarks, and data from relevant research works. The suppliers of Flycloud will be evaluated and analysed through the SCOR and Supplier Preferencing models, whereas other comparative studies of best practices and indexes in the industry will be adopted in determining the appropriate procurement and logistic policies. Finally, the following report will develop a sound strategic plan to help the Flycloud board regain the company lost ground and become operationally sound and profitable again.

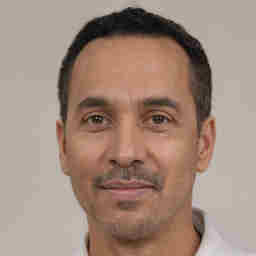

Cross functional drivers of supply chain in a globally competitive context

Globalization and Its Impact on Supply Chain Strategies

Supply chain issues that Flycloud faces must be discussed in the field of globalization, wherein trans-disciplinary forces define the strategies for procurement, business processes, and market position. The industry of aerodynamics has shifted to supply chain dependency with their suppliers, logistics, and innovations on a global basis. However, Flycloud’s current problems such as weak supplier relations, slow delivery of spare parts, and improper outsourcing show that the company has not harnessed these globalization trends. Hence, the importance of flexibility, reliability, and sustainability in the supply chain is imminent to restore Flycloud to its former dominance (Vidrova, 2020).

Supplier Relationship Management and Its Challenges

Another cross-functional driver that is problematic for FlyCloud is supplier relationship management and it has deteriorated due to ineffective and improper integration. North Star Aircraft Limited, a strategic supplier of this company has withdrawn the supply of spare parts and maintenance services from the company. This factor can be classified within the trends in supplier preferencing where suppliers identify the better clients, primarily those with whom they can have extended contract management. To align this, Flycloud has to adopt appropriate SRM deploying the Kraljic Matrix to categorize suppliers concerning risk and value. Promoting controversy, implementing vendor scorecards, and offering performance incentives are the ways to achieve commitment from the suppliers (Sheth and Sharma, 1997).

Outsourcing in a Globalized Economy and Its Implications

The fourth and most significant factor is incorporating the effects of outsourcing in the globalized economy, especially in IT and catering services. Many problems, that Flycloud encountered with the outsourced contracts include check-in tangle- some passengers have never checked in their bags, failure in check-in systems, and food orders that have been delayed. Competitive outlets such as Emirates Airline and Singapore Airline have, therefore, enhanced their outsourcing models by developing hybrid strategies with crucial operations retained in-house while outsourcing the less important functions considering the implications of inadequate service delivery at definite service levels (Hirschheim and Dibbern, 2009).

Ethical and Cultural Challenges in Procurement

Besides, ethical and cultural aspect in procurement are the key challenges that gain vital importance with supply chain management in a global scenario. The industry under consideration often buys consumables, aircraft spare parts, and IT services from countries that may be associated with ethical sourcing, labour rights, and legal requirements violations in Asian countries. This means that Flycloud may be vulnerable to these regions without a clear evaluation mechanism for its suppliers, thus putting the organization at risk of reputational losses. The use of sustainable procurement policies ensures that the company makes progress towards compliance, with the help of best practices set by such standards as ISO 20400 (Esan, Ajayi and Olawale, 2024).

Financial Stability and Sources of Innovation in Business Models

Moreover, financial stability and sources of innovation of new business models are an essential part of Flycloud’s recovery process. Through leasing as a business model, refurbishing aircraft, and backward integration there have been proven trends of more aircraft being leased than being bought by many airlines. Flycloud has to examine these models about both financial efficiency and the long-term effectiveness of the intended actions. By embracing the procurement theories and systems as well as the viable logistics issues and supplier management systems, Flycloud can shift opportunities with globalization trends and regain the competitive advantage in the Middle Eastern aviation industry (Rudevska et al., 2024).

Figure 1: Cross functional drivers of supply chain in a globally competitive context

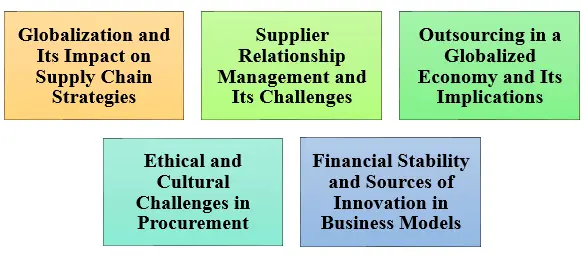

A range of relevant theories and concepts that impact on sourcing decisions in supply chain management

One of these important organizational concepts is Transaction Cost Economics (TCE) which helps determine whether it would be more profitable for an organization to produce a specific product or to acquire it from others. In the case of Flycloud, for outsourced IT and catering services, it indicated a high level of transaction costs because of contractual skills microdeletion and supplier problems. The facets of the TCE theory will help Flycloud to decide whether it is more beneficial to perform selected operations internally or negotiate changes to the current contracts to attain more rigid terms of service level agreements (MacCarthy et al., 2016).

According to Resource-Based View, the strategic resources and capabilities held within a firm determine a firm’s competitive advantage. Applying this to Flycloud, the owners question whether internalization of major organizational purchasing duties among them aircraft maintenance and supply chain management would be a cost-effective and sustainable source of competitive edge than outsourcing (Fayezi and Zomorrodi, 2015).

Another tool used in sourcing strategy is the Kraljic Matrix which evaluates suppliers according to their risks of impact and profit. These poor supplier relations suggest that Flycloud is yet another company that needs to segment its suppliers and devise an engagement approach based on the appraisal results. For example, important suppliers such as Super Turbines need to be bought with high cooperation while other unimportant suppliers could be sourced through bidding (Caniëls and Gelderman, 2005).

Furthermore, frameworks of Supply Chain Risk Management identify the necessity of managing various risks, which are of geographical natures like supply disruption, ethical issues, or volatile fuel prices. Spare parts delivery delays and volatility in the price of procurement are something that affect Flycloud, and that makes it crucial for the organization to diversify and scenario plan (Sanderson et al., 2015).

Figure 2: Range of relevant theories

Current Issues Facing Global Supply Chains and Market Environment Assessment

Geopolitical risks such as conflict, trade wars, and political sanctions are some of the most critical factors that impact supply chain management around the world currently. Disputes like the US-China trade war and Russia-West sanctions have led to prohibition, high tariffs on exports, and a fluctuating supply chain. The airlines being importers/exporters of various products such as aircraft parts, fuel, and technology are vulnerable to the volatility of the import/export policies and restrictions put in place by suppliers. Flycloud needs to extend the sources to different suppliers and formulate regional procurement approaches to avoid relying on politically sensitive areas (Balan, Vrat and Kumar, 2006).

Global inflation has adversely affected raw material prices, transportation costs, and supplier’s pricing strategies. The impacts of COVID-19 and the attempts to recover the economy also mean the growth of fuel prices, labour issues with shortages, and consequently, the rise of manufacturing costs. This is because for any airline company the cost of jet fuel, cost of maintenance, and the cost of paying employees’ wages have tremendously increased and thus the effect on the profit levels. While developing the procurement strategy for Flycloud, it is necessary to take into account the strategies that allow to control the costs, such as purchase volume increases, strategic contracts, and measures for fuel price hedging (Balan, Vrat and Kumar, 2006).

The aviation industry requires a focused global supply chain logistics to transport aircraft parts, food products to be served on the planes, and other replacement spare parts. However, some of the concerns that have been realized and impacted on the delivery of products include congestion at the ports, scarcity of the containers, and inefficient transport routes. Currently, we have embarked on an inefficient sea freight transshipment from Europe to the Middle East routes for Flycloud. The optimization of multimodal transportation management, for example through incorporating air freight solutions for spare parts, as well as adopting, return logistics as an effective solution that minimizes cost, can increase the agility of the supply chain.

Purchasing responsibly is now a major concern of all organizations, companies, and consumers across the world owing to increased demand for sustainability practices. Aviation providers procure significant quantities of airplane parts, employee garments, and rotatable products in Asia with cheap labour and materials that may be of low standards but have social drawbacks. Managing sustainable procurement: ISO 20400 and its role in Flycloud From the publication, there is a need for the integration of ISO 20400 in sustainable procurement to focus on the following green supply chain: a) Carbon footprint b) Ethical supplier audits, and c) Waste management strategies (Investigating, 2024).

AI use in procurement has also led to real-time tracking, while AI, blockchain, and IoT in supply chains have also improved real-time tracking, predictions, and procurement. Different carriers such as Emirates and Lufthansa have taken the step of digitizing some of their procurement activities in their chains. The following are the main problems found during the analysis of procurement, namely, they are using an outdated system that has been in existence for the last ten years, they lack an integrated communication system and there are human errors in the stock postings. The optimization of the use of CPFR models with suppliers and the adoption of other demand plans driven by artificial intelligence will be useful (Özkanlısoy and Akkartal, 2021).

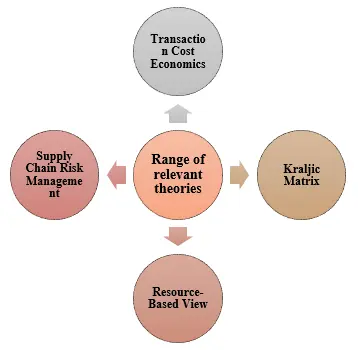

Evaluating Outsourcing Strategies and Developing Creative Solutions

Transactional vs. Strategic Outsourcing: The outsourcing affair of Flycloud is rooted in transactional outsourcing wherein the suppliers are employed merely to provide cheaper inputs and not for strategic partnerships. Consequently, there has been poor contract enforcement, lack of accountabilities, and disappearance of vendors. Instead, the airline needs to adopt the concept of strategic sourcing where the idea is to identify vendors who can be trusted for long-term association with the airline.

Offshoring and Nearshoring Considerations: At the moment, Flycloud accesses IT and catering services from third parties that are situated outside the company’s strategic operational centres and this leads to complications in communication and prolonged service delivery. Offshoring usually decreases expenses but raises issues that are associated with quality and timeliness. However, nearshoring that involves having the vendors situated in the Middle Eastern region will help in improving the delivery of services, reduce the overall time taken in getting services from the suppliers, as well as properly coordinate with the suppliers (Hwang, 2024).

Multi-Vendor vs. Single-Vendor Approach: Flycloud has exposed itself to significant risk by relying on particular arch suppliers for its IT and catering requirements; if one of the suppliers performs sub optimally, crucial operations are affected. One of the strategies for selecting the supplier is that of a multi-vendor where the different tasks are spread over several suppliers to eliminate some of the risks involved and to have more flexibility in the supply of service (Charles and Ochieng, 2023). This strategy has been previously adopted by large airlines such as Qatar Airways and British Airways which had adopted the strategies in catering and IT outsourcing to assure the reliability of service provision.

Figure 3: Evaluation of Outsourcing Strategies

Solution 1: Performance-Based Outsourcing Contracts

Now the company needs to change the type of outsourcing contracts from the fixed-term one to KPI-based, when the vendor recompense depends on the results. For instance, businesses related to catering services must still be paid for delivery while business regarding IT services expires based on regularity and response hours. Performance-based contracting makes it possible to keep the trou; because the vendors are paid based on their performance (Khosravi et al., 2022).

Solution 2: Integrated Vendor Collaboration Platforms

The breakdown of communication between Flycloud and its suppliers has brought about several inconveniences in operations. IVCP is a cloud-based application that can improve supply chain coordination since it enables instant communication, exchange of information, and work management in real-time (Khan et al., 2022). Company can even incorporate this platform with Flycloud’s ERP platform which enables the users who are in the procurement teams to track the delivery of services, vendor performance, and problems that are recurring.

Solution 3: Hybrid Outsourcing Model for IT Services

Based on the experience of Flycloud in IT outsourcing failures, the best solution is a mixed structure that includes both internal and outsourced teams. While the airline needs to outsource some of its functions as a way of cutting costs, certain essential functions should be retained within the airline company such as security management, and provision of customer-facing applications among others while functions such as data storage, software development should be outsourced. This strategy means that Flycloud is in a position where it still manages the important systems but enjoys the benefits of outsourcing which comes with a smaller cost.

Solution 4: Supplier Relationship Development Program

The fact that Flycloud has some bad blood with its vendors shows the necessity of engaging suppliers. To support the main objectives of SRDP, which include; successful vendor assessments, periodic training sessions, and incentive structures, it will be suitable to choose a key supplier; whereby Flycloud business top purchasing needs can be championed by vendors. From the joint innovation projects and combined risk management strategies, the various players such as Emirates Airlines have developed strong supplier relations (Abbasi et al., 2024).

Solution 5: Outsourcing Risk Mitigation Framework

To mitigate such risks, Flycloud needs to put in place the following risk mitigation measures:

Solution 6: Ethical and Sustainable Outsourcing Policies

Especially, hiring flying cloud waiters can have certain ethical problems: labour relations and a source of food. Therefore, to meet the international sustainability standards, the following recommendations should be adopted as guidelines to drive Flycloud:

Evaluate multi-model systems and shipping strategies applied globally

Intermodal logistics is very crucial in managerial decision-making in the supply chain since it incorporates the use of air, sea, rail, and road transport systems. Such systems shield providers from bottlenecks, suppliers, and purchasers avoid intercarrier hand-offs (Kumar, Parida and Swami, 2013). As for Flycloud, the main inefficiencies of their procurement are a slow turnover of rotating spares and uneconomic sea freight routes, which makes it necessary to assess the effectiveness of the multimodal and shipping options. They optimize the overall cost since it is cheaper to transport large quantities of products via sea or rail and only transport the perishable or speedy products through air transport (Tuzkaya, Onut and Tuzkaya, 2014). They also enhance dependency through the availability of other modes in cases of disruption and are environmentally friendly regarding carbon foot printing. DHL, FedEx, Maersk, and others apply such multimodal strategies to achieve better efficiency and cost, time, and environmental factors for complex supply chain operations (Guo et al., 2024).

Shipping strategies also affect the logistics performance, based on their appropriateness to the existing nature and requirements of an industry. JIT means goods are shipped as they are required resulting in low stocks and hence low stock costs; however, due to delayed Flycloud’s spare part delivery these ideas call for a JIT with buffer stocks for better operational efficiency. Another criticism that has been made about the holding company catering in Dubai is that the organization is not efficient the hub-and-spoke network model of distribution where factories deliver products to hubs and they are then distributed to various companies can be employed to address the issue at Flycloud (Wang, Wu and Yuen, 2023). Also, reverse logistics, an important factor in aircraft maintenance, enables the overhaul and remanufacturing of aviation components, thus lowering procurement and waste costs.

Thus, to improve its operations, it must employ a multi-model transport strategy that includes sea freight for the low value, bulk OEM spare, and air freight for the high value, time-sensitive rotating parts. Thus, the introduction of logistics optimization that would involve the use of real-time tracking of products as well as incorporating route planning using artificial intelligence, will not only reduce cost but also minimize the time taken for procurement which will make Flycloud a sustainable airline in the market (Wang, Wu and Yuen, 2023).

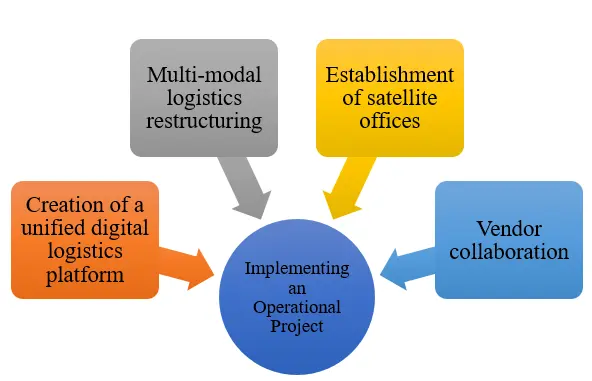

Implementing an Operational Project to Address International Logistics Challenges

Figure 4: Implementing an Operational Project to Address International Logistics Challenges

Analysis of Warehousing and Inventory Management Issues in Flycloud

Comprehensive Action Plan for Warehousing and Inventory Management at Flycloud

| Problem/Issue | Action Plan | Expected Outcome | Timeline |

|---|---|---|---|

| Excessive Inventory Holding Costs | Implement Economic Order Quantity (EOQ) and Periodic Review Replenishment System to optimize inventory levels. | Reduced inventory carrying costs and minimized surplus/expired stock. | 3-6 months |

| Stock Shortages Leading to Maintenance Delays | Use AI-driven demand forecasting models to align procurement with maintenance schedules. | Improved spare part availability and reduced aircraft downtime. | 4-8 months |

| Lack of Real-Time Inventory Visibility | Integrate an Automated Inventory Management System with RFID tracking and IoT sensors. | Enhanced tracking, improved stock accuracy, and reduced human errors (Larutama et al., 2022). | 6-12 months |

| Disorganized Warehouse Operations | Restructure warehouse layout based on ABC analysis, prioritizing frequently used items. Implement barcode scanning for real-time stock updates (Prashanth et al., 2024). | Faster retrieval times, reduced misplacements, and improved workflow efficiency. | 3-6 months |

| Disconnection Between Procurement and Warehouse Teams | Introduce an ERP-integrated inventory control system to connect procurement, maintenance, and suppliers. | Better communication, streamlined procurement, and faster order fulfillment. | 6-9 months |

| Delayed Vendor Shipments Due to Poor Coordination | Implement Collaborative Planning, Forecasting, and Replenishment (CPFR) models with key suppliers. | Improved supplier relationships, reduced lead times, and timely deliveries. | 6-12 months |

| Strained Supplier Relationships Due to Late Payments | Establish a Vendor Performance Management System with incentive-based contracts and timely payment schedules. | Stronger supplier partnerships, improved trust, and reliable procurement cycles. | 3-6 months |

| High Operational Costs Due to Inefficiencies | Adopt automated warehouse robotics and AI-driven stock optimization tools (Shivam and Gupta, 2024). | Lower labour costs, increased efficiency, and enhanced warehouse productivity. | 12-18 months |

Critical Review of Approaches for Selecting Logistics Modes and Physical Distribution Strategies

1.1 Cost-Based Approach

The cost-based approach maintains productivity by looking for ways to reduce the costs of transporting goods and services while maintaining quality. This is again a technique existing firms use to determine total direct costs such as freight charges, customs duties, insurance, and warehousing costs which all fall under total landed costs of a product (Lemon and Verhoef, 2016). In the case of Flycloud, saving non-urgent spare parts through sea freight instead of air freight would mean a huge difference in procurement expenses; albeit, many require frequent adjustments in the inventory.

1.2 Speed and Service Level Approach

This is a model that focuses on the speed of delivery and the reliability of the services, which can benefit companies requiring JIT logistics for their operations like the aviation industry. Air freight which is very expensive is preferred when it comes to spare parts especially those that can halt the functioning of an aircraft (Vijayvargiya and Dey, 2010). Thus, an ideal Freight Solution for Flycloud would involve using air for handling urgent shipments while sea or rail transport for the rest of the shipments most of the time.

1.3 Sustainability-Focused Approach

The effect that has occurred due to the enhancement of environmental conservation has forced organizations to adopt an environmentally friendly supply chain. These include the EU Green Freight Strategy which encourages a modal shift to rail and sea transport instead of road and air transport (Rezig et al., 2024). Flycloud can also conduct research on other fuels, purchase carbon offset projects, and reduce its flight track and distance to reduce its carbon footprint while enhancing its operations.

1.4 Risk and Reliability Assessment

The risk management approach is used to assess risks like geopolitical risks, supplier risks, and transport risks in the supply chain. Consequently, adapting to Flycloud’s current supply chain disruptions; partnering with various logistics providers; acquisition of other supply-line routes; and supply chain tracking technologies would facilitate improvement of the overall supply chain stability (Kritchanchai et al., 2024).

Physical distribution plans directly affect the storage, rather, how goods are stocked, transported, and delivered to their ultimate consumers. Relatedly, for Flycloud, inadequate vendor management, slow spare part replenishment, and haphazard warehousing are clear signs that the firm requires a competitive distribution strategy.

2.1 Hub-and-Spoke Model

This commonly used strategy leads to the focus of the distribution facilities to minimize transportation issues. Some of the major players in the aviation industry such as Emirates Airlines and Lufthansa Airlines employ this model in the dispatching of spare parts (Affran and Asare, 2019). Flycloud should consider changing its main distribution centre from the Middle East and more specifically Dubai to Oman or Saudi Arabia with a higher demand.

2.2 Just-in-Time (JIT) Distribution

These inventories make sure that stock is only ordered when it is needed because JIT does not permanently keep inventories. Although successful in highly active industries, this scenario is apparent with the Flycloud’s issues of lack of spare parts to support JIT implementation. Rather, it is preferable to use a hybrid JIT strategy with safety stocks which helps to maintain a low cost and a high degree of operating reliability (Kim et al., 2010).

2.3 Reverse Logistics Strategy

This is important since it deals with product recalls, warranty, and repair of products or any other products that need to be returned. Most of the carriers today order, buy, and redesign spare parts to lower their purchase prices. Rotating spare management should be in a structured reverse logistics framework that would give Flycloud the ability to turn around the products quickly and with minimal wastage (Andrejić, Pajić and Kilibarda, 2023).

2.4 Omni-Channel Distribution

Technological application of omni-channel brings together multiple transport channels in direct shipping, distribution centres near the delivery point, and VMI (Vendor Managed Inventory). It is also possible for Flycloud to engage with suppliers to set up regional fulfilment centres, which would help in increasing the supply of spare parts and lower on time (Wei and Dong, 2022).

Two supply chain management system models

The Supply Chain Operations Reference (SCOR) Model is an internationally accepted framework to measure and improve the Project Supply Chain performance. Created by the Supply Chain Council, it is a set of guidelines that define how the supply chain functions with five processes: Plan, Source, Make, Deliver, and Return. The articulated components can thus be implemented to achieve effortless integration to optimize an organization’s ability to deliver within the shortest time, at a lesser cost. For Flycloud. It is realized that due to various procurement issues and logistics hold-ups affecting operation outcomes, the adoption of the SCOR model will improve the flow and coordination of the SCM. The “Plan” stage of SCOR will enable Flycloud to establish accurate tools regarding spare parts acquisition to match with the actual maintenance requirements to avoid either stock-out situations, and at the same time reduce excessive holding costs (Lockamy and McCormack, 2004). The “Source” phase has the potential to enhance the selection of the vendor by providing Supplier Performance Metrics to enhance the adequacy of Procurement decisions. Moreover, the SCOR model improves the capability of using advanced planning and scheduling (APS) by the combination of predictive analytics and AI decision-making. Based on the above-mentioned points, Flycloud can apply SCOR performance benchmarks on supplier contracts so that Flycloud can control the lead time and deliver the parts on time. In industries, particularly aviation where there are significant losses due to time for planes not in operation, the set APS greatly fostered by SCOR can help in regulating the inventory and scheduling of maintenance thus keeping such downtime as minimal as possible (Thilakarathna, Dharmawardana and Rupasinghe, 2015).

The Collaborative Planning, Forecasting, and Replenishment (CPFR) Model is another of the most commonly known supply chain management frameworks that focuses on joint decision-making. CPFR makes it possible to share the information and plans demand forecasts and timings; all of these aspects are improved in synchronization. In the case of Flycloud, supplier misalignment, and inadequate inventory planning have led to such problems as spare part delivery delays besides facing expensive procurement issues. This can be solved by implementing CPFR which would involve the creation of real-time data sharing with the suppliers. It also enables Flycloud to coordinate regularly with supply chain partners such as Super Turbines and North Star Aircraft concerning forecasting and replenishment intervals, thus lowering the supply chain risk. Thus, in the context of APS, the issue of demand certainty arises, enhancing Flycloud’s opportunity to elaborate on the real-time schedule, which reacts to changing operational requirements for procurement and logistics accordingly (Yani and Aamer, 2023). By using AI in the CPFR systems, current records concerning the frequency of maintenance, lead time of the suppliers, and operational activities can be used to generate the right times that the stock must be replenished to avoid stock outages and yet avoid overstocking. As a result of CPFR, Flycloud can develop better partnerships with suppliers, manage risks associated with procurement, and increase efficiency in the distribution of spare parts.

Critical Analysis of ICT Applications Supporting CPFR Techniques

CPFR also known as Collaborative Planning, Forecasting, and Replenishment is an effective supply chain method that increases the communication, demand planning, and inventory management between supplier and buyer. With the use of the information-sharing technologies that are incorporated in the CPFR systems, a firm can minimize uncertainties, stock-out cases, and inefficiencies within the supply chain. Information and Communications Technology are immutable in the realization of CPFR because they help in real-time data sharing, data analysis, and decision-making among the partner firms. Bigger benefits might be derived from applying advanced technologies such as Artificial Intelligence (AI), blockchain, and the Internet of Things (IoT), as well as using the Enterprise Resource Planning (ERP) application in delivering values in terms of efficiency in procurement and logistics for Flycloud (Thomassen, Dreyer and Jonsson, 2013).

The supply chain, inventory, and procurement are affiliated to the ERP system making it easier to compound the operations with the suppliers for Flycloud. This, the ERP-driven CPFR method anticipates at the suppliers’ end the demand for spare parts for the maintenance of Flycloud’s aircraft to avoid overstock or stockouts. For instance, both SAP S/4HANA and Oracle Cloud ERP have enhanced real-time demand visibility for suppliers such as Super Turbines and its competitors namely North Star Aircraft. This minimises the prospect of a long and productive procurement cycle and increases the probable accuracy of forecasts and other forms of supplier responsiveness (Evangelista and Hallikas, 2022).

Other capabilities that are exhibited by the AI-powered CPFR solutions are demand forecasting and replenishment planning based on historical records, market data, and operation data. Data mining tools of a specific algorithm, namely of the category of ML, can give an anticipated number of spare parts needing replacement shortly, predictable by aircraft usage patterns, weather conditions, and disruptions of the supply chain. The efficiency is increased by the What’s App integration together with an AI-rich chatbot and virtual assistant that offers status updates, order confirmation, and supplier performance analysis (Srivastava, 2007). Today business giants like Amazon or Boeing apply AI in the form of predictive analysis for the management of inventories and suppliers to avoid any delays in restocking or disruption of operating procedures.

The implementation of CPFR in the supply chain makes the use of blockchain technology valuable since it makes the records more reliable, secure, and transparent. Flycloud can integrate blockchain smart contracts in procurement agreements, payment schedules, and supplier performance (Silvestri et al., 2024). This saves them from supplier disagreement, cuts administrative time, and effectively ensures all the interest groups work with accurate information. Some of the large players in the Supply chain industry such as Maersk, and DHL have adopted a blockchain that increases the level of transparency and accountability to discourage fraud, counterfeiting issues, and loss of consignment.

IoT-enhanced CPFR embraces the use of RFID sensors, GPS, and cloud tracking and monitoring in lanes to streamline the supply chain availability and inventory. With the help of IoT Flycloud can make feasible the tracking of spare part shipments, the status of inventory within the warehouse, and performance of supplier deliveries. This gets rid of the supply chain blind areas to ensure that replenishment schedules are realigned depending on the current flow of activities (Sallam, Mohamed and Mohamed, 2023). Currently, many companies including FedEx and Lufthansa incorporated the use of IoT sensors in tracking shipments to avoid delays in planning.

The elements of ICT such as ERP, AI, Blockchain, as well as IoT help in revamping the entire CPFR process, collaboration with suppliers, and logistics. Through the utilization of these technologies, Flycloud will be in a position to enhance the precision of the forecasts of demand, minimize risks in procurement, and deliver real-time supply chain visibility, which will lead to the enhancement of procuring power of Flycloud as well as the general operational effectiveness.

Critical Discussion on Supplier Relationship Management Using SCOR Model

Supplier Relationship Management (SRM) is the act of professionally managing relations with suppliers to optimize the value that can be obtained and the efficiency of operations. In the case of Flycloud, there is unreliable access to spare part suppliers to Super Turbines and North Star Aircraft Limited which has affected deliveries, minor supplier flexibility, and operation interruption. All of these point to inadequate supplier interaction, untimely contract management, and inability to provide integrated planning systems. To fix these problems, Flycloud needs to adopt the SCOR or Supply Chain Operations Reference model for five processes that encompass supplier management to enhance procurement effectiveness (Issah, Aidoo-Acquah and Eric, 2024).

Of most significance, is the Plan phase of the SCOR model which focuses on demand forecasting, procurement planning, and supplier assessment. Experienced excessive expiring/surplus spares at an amount of $5 million annually, which shows poor centralized supplier demand management. Adopting the automation of forecasting in correlation with suppliers, the procurement schedules will match the actual maintenance of the aircraft and eliminate instances of holding excess inventory or experiencing shortages of spare parts. Vendor identification and evaluation, choosing the suppliers or manufacturers, and forming partnerships as well as signing the supply agreements constitute the Source phase (Issah, Aidoo-Acquah and Eric, 2024). Additional obstacles have been caused by Flycloud’s inadequate negotiation of outsourcing contracts such that check-in system repairs are delayed and food delivery goes wrong leading to a loss in customers’ satisfaction. This ensures that Flycloud is in a position to rate suppliers about certain factors such as reliability, cost for the services offered, and quality in service delivery hence only allowing quality suppliers into its network. That is why the best improvement in Make, which addresses production and assembly, can be considered in Flycloud’s context as the refurbishment/repurposing of aircraft parts. The airline has recently modified two older models of Boeing 777 for carrying cargo for its catering arm, but structural problems that deter for efficient delivery of food supplies to Oman and Saudi Arabian airlines have occurred. Through an effective supplier partnership, Flycloud acquires the benefits of having spare parts on call for the conversion of several aircraft and also enhances its production cycle (Yang et al., 2023). The delivery phase of the SCOR model is important whereby the organisation has to ensure the timely delivery of spare parts and catering Supplies. This has made the replenishment of spare parts through uneconomic sea freight transshipment routes from Europe to the Middle East take longer which has an impact on the maintenance turnaround. To address this issue, to minimize the catering logistics’ reliance on Dubai, and to increase the efficiency of the delivery system, the company has to implement a multiple logistical system involving central distribution shops in Oman and Saudi Arabia. The fourth and last stage is the return policy which entails the return of substandard products and holding the suppliers responsible for their failures. Flycloud has experienced some operational problems in as much as they have not been having defective OEM spares for the planes which have been delaying their maintenance (Yang et al., 2023). Incorporation of a performance-based return policy on spare parts suppliers so that the vendors will bear charges for substandard spare parts will improve the suppliers’ compliance and part quality. The implementation of the SCOR model within Flycloud’s supplier management framework will in turn increase supplier relations, enhance the procurement process, and decrease operational hitches. With the development of performance evaluation for supplier management, demands matching with supply, and a comprehensive logistics plan, Flycloud could recover its lost competitiveness in the Middle Eastern aviation industry.

Evaluation of Commercial and Operational Financial Statements and Agreements

Using and analysing financial statements and agreements is essential to determine an organization’s profitability, liquidity, and efficiency. In Flycloud’s instance, financial mismanagement leads to issues such as supplier defaults, high operation expenses, and long procurement cycles that compromise cash flow and supply chain management. From an analysis of Flycloud’s commercial and operational financial statements, there are serious defects that exist in the company’s profitability, asset turnover, and working capital budgets, which will require managerial scheduling and supply chain reconstruction. The analysis of the financial statement of Rack Bearing Limited (Flycloud’s supplier) has revealed that there are decreases in the profitability and ratios of the company within three years. The profit margin reduced from 9.12% in the year ending December 2015 to 8.63% in the year ending December 2016 and slightly increased to 9.22% in the year ending December 2017, meaning that there was poor control of costs and inconsistent revenues. Profitability also reduced from 13.12% in 2015 to 9.25% in 2017 proving the poor financial health reality of the company. Rising procurement and operation costs could be the reason hence, Flyers must review the current contracts in line with its suppliers based on performance and cost control measures (Affran and Asare, 2019). Liquidity ratios are another weak aspect considering the current ratio which reduced from 1.62 in 2015 to 1.21 in 2017 and the quick ratio which also decreased from 0.98 in 2015 to 0.55 in 2017, which signals poor management of cash flow as well as the inability to meet short term obligations. This may be attributed to the late payments from Flycloud meaning that suppliers are placed under pressure and thus take up to two months to deliver. The use of blockchain for electronic payment can increase the visibility of payments to suppliers and facilitate the delivery of contracts on procurement relationships. The stock turnover ratio ratched down from the previous year from 5.1 in 2015 to 6.12 in 2016 and further dropped to 4.25 in 2017 due to the issues of excess inventory and holding costs. This is an implication of high surplus and ill-maintained expired spares that have led Flycloud to experience a net operating loss of $5 million in a year. Applying CPFR models based on artificial intelligence technologies and Economic Order Quantity can minimize the amount of funds unprofitably tied to inventory (Balan, Vrat and Kumar, 2006).

Last of all, the gearing ratio rose from 13.15% in 2015 to 21.25% in 2017, which showed the reliance of the firm on debt financing. Flycloud's $5 billion loss that resulted from bad modelling on the acquisition of airplanes gives credence to the need to develop a Whole Life Costing (WLC) that would recommend the sustainable cost of capital asset acquisitions in the long run.

Developing a Total Cost Strategy for Capital Equipment Acquisition

A Total Cost Strategy (TCS) for acquiring capital equipment takes into consideration the acquisition cost but also other costs that are associated with the acquisition of capital equipment including operational costs, and costs of financing among others costs of retirement of the equipment. The earlier instance which took place at Flycloud, whereby it went $5 billion of the cellular cost overruns in obtaining Boeing 777 aircraft as a result of inept financing strategies reinforces such requirements for WLC.

Elements of the total cost strategy

Total Cost Calculation for Aircraft Acquisition

For example, if Flycloud is acquiring 10 new aircrafts and each aircraft costs $250 million, then the total capital cost would be $2.5 billion. The whole life cost (WLC) has been divided into quarters for a period of fifteen years, as detailed below:

|

Cost Component |

Cost per Aircraft ($M) |

Total Cost (10 Aircrafts, $M) |

% of Total Cost |

|

Purchase Price |

250.00 |

2,500.00 |

50% |

|

Financing Cost (5% annual interest over 15 years) |

75.00 |

750.00 |

15% |

|

Operational Cost (Fuel, crew, insurance - $12M/year per aircraft) |

180.00 |

1,800.00 |

36% |

|

Maintenance & Repair ($4M/year per aircraft) |

60.00 |

600.00 |

12% |

|

Depreciation (50% over 15 years, residual value $125M/aircraft) |

-125.00 |

-1,250.00 |

-25% |

|

Decommissioning Cost |

10.00 |

100.00 |

2% |

|

Total Whole Life Cost |

450.00 |

4,500.00 |

100% |

Key findings from the total Tariff analysis

This overall cost over time equals 4.5 billion US dollars, which is 80% more than the cost of the aircraft, which is only 2.5 billion US dollars.

Fuel, crew, and insurance account for the highest expenditure at 36%, and any improvements made to them will bring significant changes.

Depreciation was also described as severely diminishing the long-term worth, and this supported the call to seek ways to improve resale value such as leasing rather than buying.

Credit expenses made up 15% and it means that if better interest rates could be negotiated or to go for leasing options, costs could be probably cut down by a lot (Esan, Ajayi and Olawale, 2024).

Strategic Recommendations for Cost Optimization

Critical Review of the Impact of Digital Payment Methods on Supply Chain and Logistics

Digital payment has therefore brought positive change to supply chain and logistics by increasing payment speed, making transactions more secure, and making suppliers real-time. In the case of Flycloud, a non-effective payment system has contributed to such consequences as supplier failure, delayed delivery, and bad relations with vendors. Blockchain-generated payments, automated invoices, or the digital e-payment system can be useful in addressing these concerns given they enhance timely payments, reduce chances of errors, and make procurement cycles clearer. The analysis of the financial performance of Rack Bearing Limited shows low solvency and decreasing profitability, which underlines the importance of placement of an appropriate payment system aimed at improving the cash flow management and suppliers’ confidence (Evangelista and Hallikas, 2022).

E-payment systems are significant in the process of the procurement cycle and linking the buyer with the supplier to facilitate proper financial transactions. Digital payment methods in supply chain management reduce the problems of delayed payments which have time and again been encountered at Flycloud. This implies poor liquidity to meet current obligations; a reduction in the current ratio from 1.62 in 2015 to 1.21 in 2017, may relate to delayed payments from clients such as Flycloud thus exerting credit pressure on Rack Bearing Limited. Such harms could be reduced by computerization of billing and the process of invoicing to avoid suppliers’ cash flow problems.

Supplier financial risks are always essential to every supply chain, and the utilization of supplier financial appraisals can sometimes offset those risks. Analyzing the profitability ratio, it established that the supplier has lower profitability levels than the previous year, and considered low efficiency and increased operation cost as factors that led to the reduction of the profitability ratio from 13.12% in 2015 to 9.25% in 2017. The acid-test ratio which measures the ability of a supplier to pay his current obligations without incurring additional sources of funds has reduced from a ratio of 0.98 in the year 2015 to 0.55 in the year 2017 which outlines that the company is experiencing deteriorating liquidity. The above conditions indicate that suppliers are in a weak financial position and are presented here as the weaknesses facing Flycloud in dealing with them. Another expected advantage of using digital payment solutions such as blockchain is that it offers far lesser payment risks to the suppliers for money that is due, which leads to fewer chances of supply chain money problems and hence the strain that comes with it.

Lack of integration of systems, delays in payment, and inadequate management of contracts are key challenges that have characterized the procurement cycle at Flycloud. Some procedures can be adopted in digital procurement systems such as electronic transfer of funds, smart contracts, and real-time reconciliation. Through the help of technology, procurement departments are in a position to always assess the efficiency of the suppliers, manage payments, and ensure that the suppliers fulfill the contract requirements as agreed. This level of integration eliminates differences about terms by the agreed payment arrangements hence curbing instances of dispute arising from delayed payment. There is a decline from the value of 23.15% in 2015 to 14.23% in 2017 which indicates that Rack Bearing Limited is not utilizing its assets efficiently and it may be attributed to long procurement cycles and wrong capital investments. With the inclusion of real-time digital payment, the procurement expense can be optimized, thus the overall responsiveness of the supply line can be improved by Flycloud (Guo et al., 2024).

Supply chain finance is the application of the blockchain and has been widely regarded to increase its security, and transparency and improve efficiency in the conduct of financial business. Smart contracts in global supply chain management can also be implemented in enforcing supplier payment in a way that the payee receives the payment after delivering the goods due to some agreed conditions being met. This reduces such drawbacks of business transactions as embezzlement and difficulties that Flycloud Company has experienced before – advance payment without the provision of services. One of the advantages of blockchain is that all the financial transactions recorded in the database cannot be altered thus making the relation with the suppliers and buyers more trustworthy. Moreover, blockchain can also support supply chain financing by solving issues related to invoice processing and discounting, avoiding third-party intermediation, and is cost-effective to execute.

Similarly, the stock turnover ratio of Rack Bearing Limited rose to 6.12 in 2016 and declined to 4.25 in 2017 thus inferring inefficiency in stock control. These could be due to, for instance, delayed supplier payment, resulting in supply constraints, and slow inventory turnover. This paper explores the role of digital payment solutions that allow the implementation of JIT payment systems by linking payment to the supply chain to supplement supplier’s cash flow needs while maintaining uninterrupted operations. This could be integrated with the AI of the digital payment systems to improve the accuracy of the forecasts that Flycloud can use to optimize the expenses it incurs in buying stocks it does not need to hold in large quantities.

Another financial risk of Flycloud is the increase of gearing ratio in Rack Bearing Limited whereby it has risen from 13.15% in 2015 to 21.25% in 2017. A higher gearing ratio implies more use of borrowed funds and hence a higher risk of stockholder risk and supplier risk. Buyers gain more suppliers’ trust in SCF because Flycloud enables them to provide a range of funding options such as supply chain finance and dynamic discounting instead of expensive short-term funding (Lemon and Verhoef, 2016).

The role of digital payment methods in supply chain and logistics cannot be underestimated as several problems with late payment, supplier’s working capital problems and procurement issues can be solved. This means that Rack Bearing Limited needs to operate an efficient system of payment to reduce cases of a declined liquidity ratio and other poor profitability ratios evident from the financial statements. With the help of the blockchain, AI-based predictions of the cost, and the automation of contractual purchasing cycles, Flycloud can provide more stable financial conditions, strengthen business ties with suppliers, and increase the overall resistance of the supply chain. Solving these financial issues by adopting digital solutions will foster flexibility and competitiveness of Flycloud when operating in the aviation market and will lead to the company’s sustainable development and high-performance level.

Conclusion

Analysing Flycloud’s procurement, supply chain, and financial issues in this paper revealed some inefficiencies that would impede the growth of the airline. This paper encompasses failed supplier relationships, inventory issues, outsourcing issues, and various financial issues that have led to operational interferences and financial deficits. To improve demand forecast, supplier management as well as logistics management, strategic procurement models including SCOR and CPFR should be adopted. Another big issue was that Flycloud’s relationships with their suppliers were tense, especially with Super Turbines and North Star Aircraft Limited this meant that they would take longer time to provide spare parts and would not be willing to cooperate fully. Originally, the Kraljic Matrix was developed, later followed by the Supplier Preferencing Model to categorize the vendors) Arial exhibits a well-structured supplier management approach in that it categorizes the vendors according to their risk and value. Moreover, outsourcing failures in IT and catering services demanded performance-oriented contracts and numerous interconnected vendor management systems to enhance service quality. Based on data from Flycloud’s inventory and warehousing, excessive and expiring stock caused the business to lose $5 million every year, which was why it required AI in demand forecasting, EOQ, as well as automated inventory management. Likewise, logistics related to the airline such as uneconomical sea freight routes and slow rotating spare shipments called for a switch to multi-modal transportation and regional distribution centres.

Issues such as inconsistent payments, non-adherence to appropriate payment timetables, high gearing ratios, and suppliers’ default promoted the adoption of digital payment regimes and block-chain technology in transactions, and automation of the payment cycle. Finally, to cut costs as well as enhance the use of available equipment capital equipment acquisition policy that implements Whole Life Costing was recommended.

References

1. Introduction to Design and Verification of Electrical Installation Assignment The Skinner’s Automotive Electronics and...View and Download

LO1 Understand different forms of communication and their application 1.1 Explain different forms of communication and their...View and Download

Introduction To Unit 4: Wider Professional Practice And Development This assignment sample focuses on the key concepts of...View and Download

Introduction to Unit 06: Managing a Successful Business Project Managing a successful business project requires a clear...View and Download

Introduction Enhance your social science assignment with Assignment Help UK, exploring how education and crime influence social...View and Download

Introduction Get free samples written by our Top-Notch subject experts for taking assignment...View and Download