+44 75754 30035 help@rapidassignmenthelp.co.uk

offer

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

🎁Special Offer 🎁 Discounts - Up to 55% OFF!

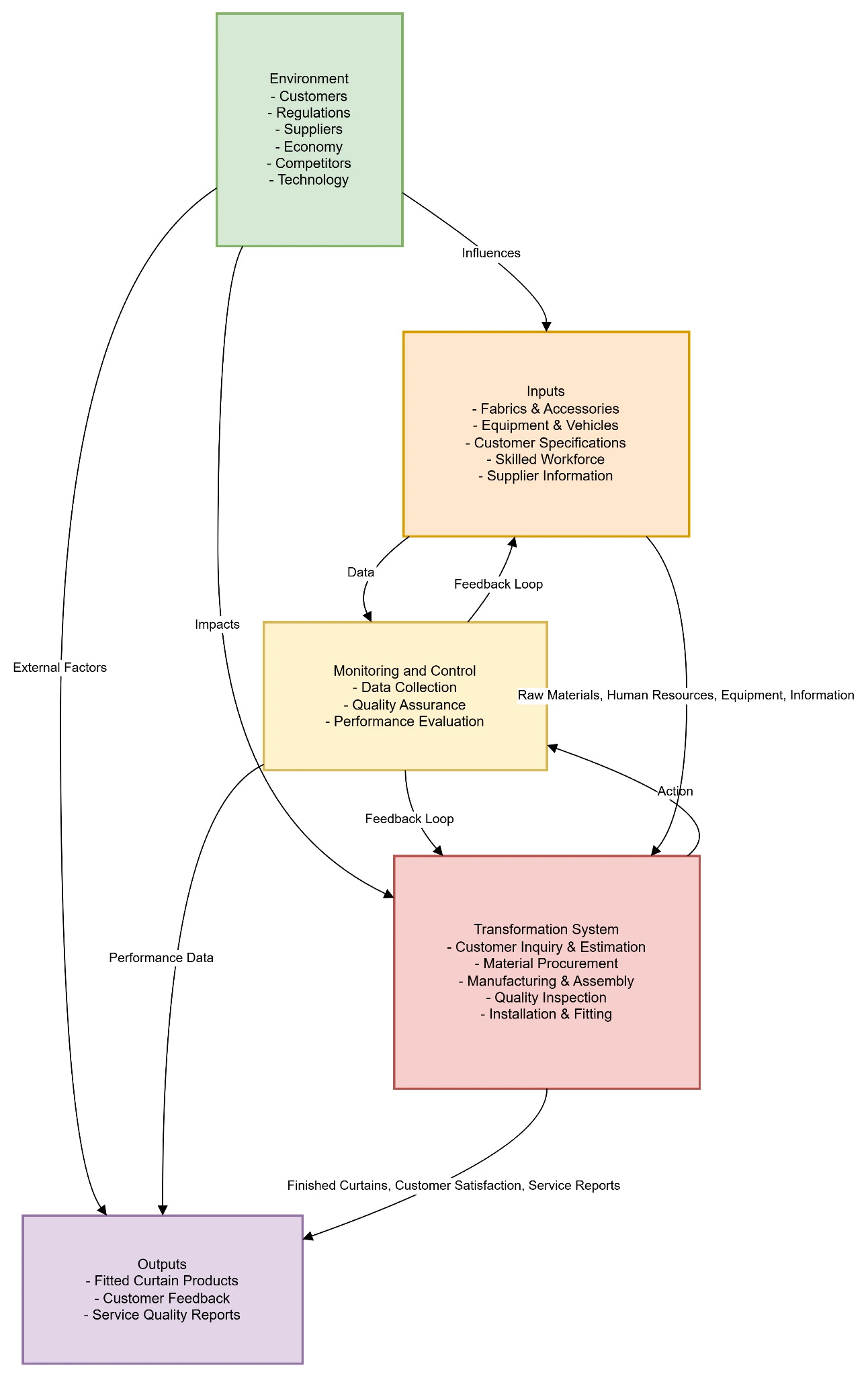

The operational flow model at SKOPOS is structured around the Input–Transformation–Output (ITO) framework, which explains how resources are converted into finished curtain solutions. Inputs such as materials, information, skilled labour, and equipment move through coordinated production and installation stages to produce customised outputs. The transformation stage integrates design interpretation, fabrication, quality control, and on-site fitting activities, ensuring that customer specifications are accurately implemented. This model supports process visibility by defining roles and sequences of activities, which helps clarify process responsibilities, reduce inefficiencies, and maintain consistent service quality across operations.

Sample papers and reference materials clarify academic requirements and assignment structure. We offer help with writing assignments service through structured examples that reflect standard academic practice. The Operations and Supply Chain Analysis for SKOPOS Assignment Sample outlines operational flow, order execution, and supply chain structure. These materials are intended for reference purposes only.

The Input-Transformation-Output (ITO) model is a basic model used in operations management that aims at showing how inputs are transformed into outputs in the production process. Organizes work into three broad categories of work activities, the incoming resources, transformation process and the outputs (Chen 2025). This model assists in the documentation of the gaps and streamlining of services to improve on the provision of services within an organization. If these stages are adequately described, then the productivity of the business would enhance, much wastage would be eliminated and the customer customers would be satisfied.

These are obtained from some of the main suppliers such as Weavers Tekstil Sanayi ve Ticaret A.Ş, Edmund Bell & Co, Teksko Kumascilik Pazarlama, and Creative TexStyles BvBa for quality and attractive fabric. Besides fabrics, other related accessories including curtain rods and brackets, as well as tiebacks, are also required at the installation stage.

Information that relates to information inputs are; client requirements, design specifications and project requirements. Within the Operations and Supply Chain Analysis for SKOPOS, this information is acquired at the time of preliminary client consultation leading to customization. It is acquired at the time of preliminary client consultation leading to customization. It provides the design and production personnel with information on how to develop goods that meet the needs of the customers (Dubey 2024).

The human resources are the qualified practitioners whose roles are to implement the change processes in the various organizations. They consist of the sales and customer service personnel who answer inquiries and quote new projects, the estimation and procurement department that deals with acquisition of materials and the manufacturing and fitting teams charged with fabrication and installation of conservatories on site. These teams also collectively make sure that coordination and effectiveness in the delivery of service is observed.

Get assistance from our PROFESSIONAL ASSIGNMENT WRITERS to receive 100% assured AI-free and high-quality documents on time, ensuring an A+ grade in all subjects.

The input phase also involves the use of equipment and technology which are important in carrying out the process. In order to support the different operations at SKOPOS, industrial sewing machines, cutting tools, and vehicle transportation services are employed.

This is followed by the customer enquiry stage where clients offer their brief details through phone, email or the website of the company (Cui 20240. The sales team takes down peculiarities such as the preferred type of fabric, dimensions of the area that requires covering and installation types. The information is then passed to the estimation team who in turn develops quotations from the material costs, manpower costs, and time taken to produce the products.

After the customer sets his/her approval on the quotation, the procurement phase sets off. The purchasing team sources raw materials from SKOPOS’s network of suppliers. The Operations and Supply Chain Analysis for SKOPOS highlights how the purchasing team sources raw materials from SKOPOS’s network of suppliers. This includes assessment checks to ascertain that the materials used in the production of these copies/replicas are as per the company’s requirements.

The manufacturing process then occurs. It includes multiple steps:

After manufacturing, the next process is dispatching. They have packaging and transporting of the curtains ready and prepared. Organizing transport to the customer’s place to make sure that delivery is done before the stipulated time.

Finally, the last stage of the curtain products involves the fitting team fixing the completed works at the customer location. They secure the products to ensure that they are in the right positions depending on the installation processes that were made earlier as well as guarantee the functionality of the products that have been installed (Lee 2025). There is a final inspection on-site and the product assures customers that the expectant testimony of the company is achieved.

Figure 1: ITO model for SKOPOS business

The operational output that is espoused by SKOPOS entails the physical and intangible products from the change process of the unit. The main product is the fitted curtain products in accordance to the client’s requirements. They are used in business, homes, and hotel buildings; they improve the looks and usability of the structures.

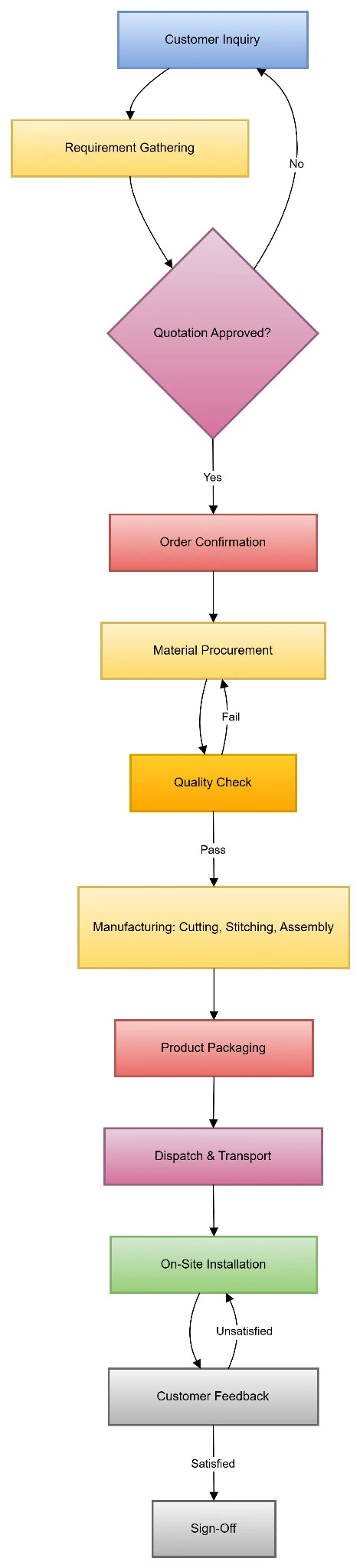

Customer order execution at SKOPOS follows a sequential process beginning with enquiry and requirement gathering, followed by estimation, production, delivery, and installation. Each stage is designed to ensure accuracy, timely execution, and alignment with client specifications. Effective coordination between sales, procurement, manufacturing, and logistics supports reliable order fulfilment and reduces delays.

Order fulfillment can be described as a process of acquiring products or services by a customer through to the installation process/phase. This covers a wide spectrum of activities some of which are sales, manufacturing, distribution as well as after installation services. Order fulfillment is paramount to SKOPOS as it continuous operation, delivery of products to customers and more importantly make them contented (Nguyen 2024). This means that through the efficient of each of these phases, the company is able to minimize mistakes and delay,, improving on its efficiency in the provision of services.

Figure 2: Process Map

The first process that one undergoes in order to begin the creation of the product and its distribution is the customer enquiry and requirement gathering process. Some of the ways that it is possible to make contact with customers is through a phone call, an email or even visiting the company’s website (Garcia and Martinez 2025). The sales team also records specifications which include choosing of fabric, size of the fabric and the method of installation. This information forms the basis for the following estimation phase.

During the estimation and quotation, the estimation team determines the cost of the materials that have to be used, the cost that will be charged to labor and the time it will take to produce a given material. The Operations and Supply Chain Analysis for SKOPOS demonstrates how a clear quotation capturing all these details is developed and forwarded to the customer. Consequently, a clear quotation that captures all these is developed and forwarded to the customer. Consequently, once this is approved, the order is acknowledged and put through for production.

The next of the stages is the procurement of materials required for the production of the product. SKOPOS sources the required fabrics, accessories, and hardware from its supplier network. It implies that quality tests are conducted to ensure that the raw materials procured are of the required standard of the company (Wang and Zhao 2024).

In this stage, basic and obtained materials are converted to the final product through a process. This stage entails cutting of fabrics and joining of the various parts that has been designed in the previous stage. Thus, to reduce irrational decoupling, the sewing team employs accurate measurement tools to minimize inconsistencies and to maintain high quality work. In order to achieve such high quality standards several checks are done at different points of the process.

After manufacturing, there is the packaging and dispatch of the products to their respective destinations. The curtains are properly folded, tagged, and enclosed to avoid possibly damaging them during transit. This delivery is planned to occur at the customer location, and thus the logistics team works at ensuring that the delivery is done on time .

Order fulfillment needs to be efficient so that it can deliver products in good time to the customers and the quality of the products should not be compromised. To help eliminate some of these issues, SKOPOS works to rethink each stage in order to shorten relevant time spans and decrease the possibility of mistakes (Fernandez and Vidal 2025). Altogether the exercise also serves to enhance the bonding with the suppliers while at the same time achieving resource management. Timely delivery enhances the positive reputation of the company in the market and ensures that the customers will continue to engage the company and its products.

The supply chain structure of SKOPOS integrates upstream suppliers and downstream customers through coordinated material, information, and service flows. Reliable supplier partnerships ensure access to quality fabrics and accessories, while an organised distribution and installation network supports timely delivery to end users. This structure strengthens operational continuity and supports consistent service outcomes.

Supply chain means a web work of supply systems showing an interfaced pattern of material, service and information in a firm’s value chain. It has also two main activities which are upstream: the supplier side whereas downstream is the customer side. In the case of SKOPOS, organizational structure of supplies and distribution should involve a complementing system for supply network architecture, supply networks, material flow, production flow, and distribution flow.

The first network is procurement that includes obtaining the incoming supply of material and services needed in production. There are many suppliers associated with SKOPOS: Weavers Tekstil, Edmund Bell & Co, Teksko Kumascilik, etc.

Transportation of materials and delivery of products is supported by different companies such as Dachser Ltd, Simpson Packaging, and Transfoam Ltd for material transportation and storage as well as good handling

The final reaches concern distribution and consumption by the end-user stakeholders of the supply network. The target consumers of SKOPOS include hotels and resorts, residential clients as well as office occupancy. This means that there are timely supplies and professional putting in place of facilities to boost its service delivery reliability.

References

Introduction Get Free Online Assignment Samples from UK's Best Assignment Help Experts to boost your academic...View and Download

Introduction to PD Portfolio Assignment Sample Professional development refers to achieving new skills through continuing...View and Download

Jurisdictional Challenges – Overview Jurisdictional complexity in international trade is due to the very transnational...View and Download

1. Introduction: Construction Methods, Materials and Technology This proposal entails the building construction techniques, the...View and Download

Introduction: Gender and Sexuality in Society In the current competitive environment, gender and sex a major issues that prevail...View and Download

Introduction - Innovative Tactics for Digital Marketing Success Relaunching of product defines brining various necessary changes...View and Download